This standard specifies requirements for M1 to M160 hexagon nuts. assigned to product grade A (up to size M16) or product grade B (for sizes above M 16). If. in special cases. nuts are to comply with specifications other than those given in this standard, e.g. regarding property class, they shall be selected in accordance with the relevant standards.

| d | P | da | dw | s | e min. | m | m1 min. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | ||||||

| M1 | 0.25 | 1 | 1.15 | 2 | 2.4 | 2.5 | 2.71 | 0.55 | 0.8 | 0.44 | |

| M1.2 | 0.25 | 1.2 | 1.4 | 2.1 | 2.9 | 3 | 3.28 | 0.75 | 1 | 0.6 | |

| M1.4 | 0.3 | 1.4 | 1.6 | 2.1 | 2.9 | 3 | 3.28 | 0.95 | 1.2 | 0.76 | |

| M1.6 | 0.35 | 1.6 | 1.84 | 2.4 | 3.02 | 3.2 | 3.41 | 1.05 | 1.3 | 0.84 | |

| M2 | 0.4 | 2 | 2.3 | 3.2 | 3.82 | 4 | 4.32 | 1.35 | 1.6 | 1.08 | |

| M2.5 | 0.45 | 2.5 | 2.9 | 4.1 | 4.82 | 5 | 5.45 | 1.75 | 2 | 1.4 | |

| M2.6 | 0.45 | 2.6 | 3 | 4.1 | 4.82 | 5 | 5.45 | 1.75 | 2 | 1.4 | |

| M3 | 0.5 | 3 | 3.45 | 4.5 | 5.32 | 5.5 | 6.01 | 2.15 | 2.4 | 1.72 | |

| M3.5 | 0.6 | 3.5 | 4 | 5 | 5.82 | 6 | 6.58 | 2.55 | 2.8 | 2.04 | |

| M4 | 0.7 | 4 | 4.6 | 5.8 | 6.78 | 7 | 7.66 | 2.9 | 3.2 | 2.32 | |

| M5 | 0.8 | 5 | 5.75 | 6.8 | 7.78 | 8 | 8.79 | 3.7 | 4 | 2.96 | |

| M6 | 1 | 6 | 6.75 | 8.8 | 9.78 | 10 | 11.05 | 4.7 | 5 | 3.76 | |

| M7 | 1 | 7 | 7.75 | 9.5 | 10.73 | 11 | 12.12 | 5.2 | 5.5 | 4.16 | |

| M8 | 1.25 | 8 | 8.75 | 11.3 | 12.73 | 13 | 14.38 | 6.14 | 6.5 | 4.91 | |

| M10 | 1.5 | 10 | 10.8 | 15.3 | 16.73 | 17 | 18.9 | 7.64 | 8 | 6.11 | |

| M12 | 1.75 | 12 | 13 | 17.2 | 18.67 | 19 | 21.1 | 9.64 | 10 | 7.71 | |

| M14 | 2 | 14 | 15.1 | 20.2 | 21.67 | 22 | 24.49 | 10.3 | 11 | 8.24 | |

| M16 | 2 | 16 | 17.3 | 22.2 | 23.67 | 24 | 26.75 | 12.3 | 13 | 9.84 | |

| M18 | 2.5 | 18 | 19.5 | 25.3 | 26.16 | 27 | 29.56 | 14.3 | 15 | 11.44 | |

| M20 | 2.5 | 20 | 21.6 | 28.2 | 29.16 | 30 | 32.95 | 14.9 | 16 | 11.92 | |

| M22 | 2.5 | 22 | 23.7 | 29.5 | 31 | 32 | 35.03 | 16.9 | 18 | 13.52 | |

| M24 | 3 | 24 | 25.9 | 33.2 | 35 | 36 | 39.55 | 17.7 | 19 | 14.16 | |

| M27 | 3 | 27 | 29.1 | 38 | 40 | 41 | 42.2 | 20.7 | 22 | 16.56 | |

| M30 | 3.5 | 30 | 32.4 | 42.7 | 45 | 46 | 50.85 | 22.7 | 24 | 18.16 | |

| M33 | 3.5 | 33 | 35.6 | 46.6 | 49 | 50 | 55.37 | 24.7 | 26 | 19.76 | |

| M36 | 4 | 36 | 38.9 | 51.1 | 53.8 | 55 | 60.79 | 27.4 | 29 | 21.92 | |

| M39 | 4 | 39 | 42.1 | 55.9 | 58.8 | 60 | 66.44 | 29.4 | 31 | 23.52 | |

| M42 | 4.5 | 42 | 45.4 | 60.6 | 63.1 | 65 | 71.3 | 32.4 | 34 | 25.9 | |

| M45 | 4.5 | 45 | 48.6 | 64.7 | 68.1 | 70 | 76.95 | 34.4 | 36 | 27.5 | |

| M48 | 5 | 48 | 51.8 | 69.4 | 73.1 | 75 | 82.6 | 36.4 | 38 | 29.1 | |

| M52 | 5 | 52 | 56.2 | 74.2 | 78.1 | 80 | 88.25 | 40.4 | 42 | 32.3 | |

| M56 | 5.5 | 56 | 60.5 | 78.7 | 82.8 | 85 | 93.56 | 43.4 | 45 | 34.7 | |

| M60 | 5.5 | 60 | 64.8 | 83.4 | 87.8 | 90 | 99.21 | 46.4 | 48 | 37.1 | |

| M64 | 6 | 64 | 69.1 | 88.2 | 92.8 | 95 | 104.86 | 49.1 | 51 | 39.3 | |

| M68 | 6 | 68 | 73.4 | 92.9 | 97.8 | 100 | 110.51 | 52.1 | 54 | 41.7 | |

| M72 | 72 | 77.8 | 97.7 | 102.8 | 105 | 116.16 | 56.1 | 58 | 44.9 | ||

| M76 | 76 | 82.1 | 102.4 | 107.8 | 110 | 121.81 | 59.1 | 61 | 47.3 | ||

| M80 | 80 | 86.4 | 107.2 | 112.8 | 115 | 127.46 | 62.1 | 64 | 49.7 | ||

| M85 | 85 | 91.8 | 111.9 | 117.8 | 120 | 133.11 | 66.1 | 68 | 52.9 | ||

| M90 | 90 | 97.2 | 121.1 | 127.5 | 130 | 144.08 | 70.1 | 72 | 56.1 | ||

| M100 | 100 | 108 | 135.4 | 142.5 | 145 | 161.02 | 78.1 | 80 | 62.5 | ||

| M110 | 110 | 119 | 144.9 | 152.5 | 155 | 172.32 | 85.8 | 88 | 68.6 | ||

| M125 | 125 | 135 | 168.6 | 177.5 | 180 | 200.57 | 97.8 | 100 | 78.2 | ||

| M140 | 140 | 151 | 185.6 | 195.4 | 200 | 220.8 | 109.8 | 112 | 87.8 | ||

| M160 | 160 | 171 | 214.1 | 225.4 | 230 | 254.70 | 125.5 | 128 | 100 | ||

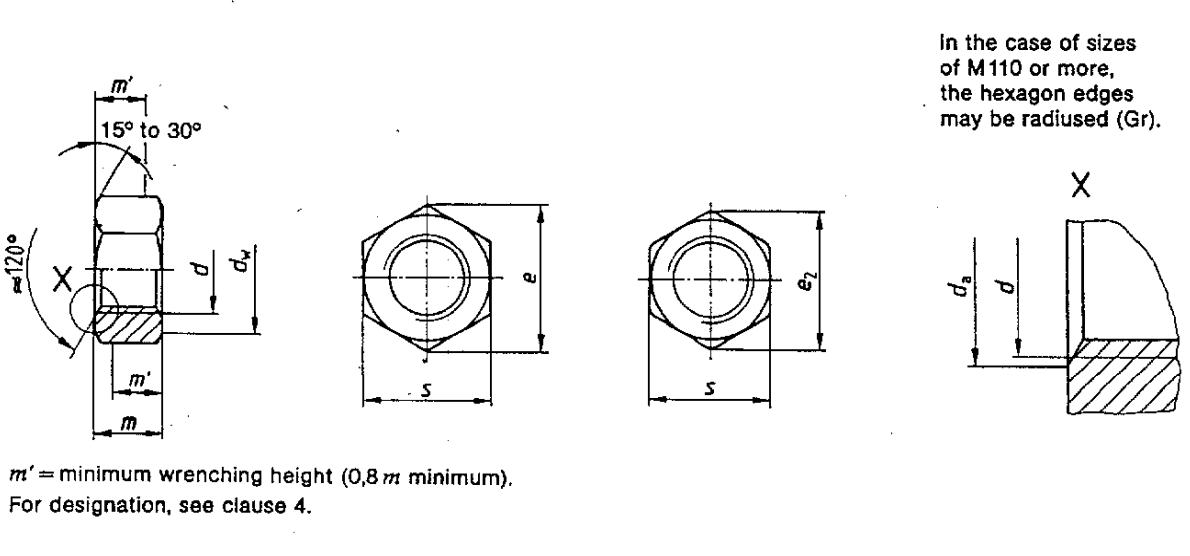

| Sizes in brackets should be avoided if possible. P= pitch of coarse thread as specified in DIN 13 Part 12. 2) As a deviation from ISO 4759 Part 1. tolerance zone h12 instead of h13 shall apply for widths across flats up to and including 4 mm. Minimum dimensions corresponding to tolerance zone h14 instead of h13 shall be permissible for M5 to M16 hot dip galvanized nuts. |

|||||||||||

| Size | Weight |

|---|---|

| M1 | 0.030 |

| M1.2 | 0.054 |

| M1.4 | 0.063 |

| M1.6 | 0.076 |

| M2 | 0.142 |

| M2.5 | 0.280 |

| M3 | 0.384 |

| M3.5 | 0.514 |

| M4 | 0.81 |

| M5 | 1.23 |

| M6 | 2.50 |

| M7 | 3.12 |

| M8 | 5.20 |

| M10 | 11.6 |

| M12 | 17.3 |

| M14 | 25.0 |

| M16 | 33.3 |

| M18 | 49.4 |

| M20 | 64.4 |

| M22 | 79 |

| M24 | 110 |

| M27 | 165 |

| M30 | 223 |

| M33 | 288 |

| M36 | 393 |

| M39 | 502 |

| M42 | 652 |

| M45 | 800 |

| M48 | 977 |

| M52 | 1220 |

| M56 | 1420 |

| M60 | 1690 |

| M64 | 1980 |

| M68 | 2300 |

| M72 | 2670 |

| M76 | 3040 |

| M80 | 3440 |

| M85 | 3930 |

| M90 | 4930 |

| M100 | 6820 |

| M110 | 8200 |

| M125 | 13000 |

| M140 | 17500 |

| M160 | 26500 |

| Material | Steel | Stainless steel | Non-ferrous metals | ||

|---|---|---|---|---|---|

| General requirements | As specified in DIN 267 Part I. | ||||

| Thread | Tolerance | 6H 1) | |||

| As specified in | DIN 13 Parts 12 and 15. | ||||

| Mechanical properties | Property class (material) | For size M 2.5 or less: 6; for sizes between M 3 and M 39: 6, d or 10; for sizes above M 39: subject to agreement. | For sizes up to M 39: A 2-70 or A4-70; for sizes above M 39: subject to agreement. | Subject to agreement. | |

| As specified in | DIN 267 Part 4 | DIN 267 Part 11 | DIN 267 Part 18 | ||

| Limit deviations, geometrical tolerances | Product grade | For sizes up to M 16: A: fot larger sizes: B. | |||

| As specified in | ISO 4759 Part 1. | ||||

| Surface finish | As processed. | Bright. | Bright. | ||

| DIN 267 Part 2 shall apply with regard to surface roughness. DIN 267 Part 20 shall apply with regard to permissible surlace discontinuities. DIN 267 Part 21 5hail apply with regard to the widening test. DIN 267 Part 9 shall apply wlth regard to electroplating.) DIN 267 Part 10 shall apply with regard to hot dip galvanizing. |

|||||

| Acceptance inspection | DIN 267 Part 5 shall apply with regard to acceptance inspection. | ||||

| l) Where a protective coating is applied. e.g. an electroplated coating complying with DIN 267 Part 9, depending on the coating thickness requlred. It may be necessary, particularly in the caso of tolerance class OH nuts. to select a larger fundamental deviatlon than that assigned to tha H posltion (800 DIN 267 Part 9). ThiG, impair the (631stance ot the bolt/nut assembly to stripping. | |||||